CATIA V6 R2025 – Complete 2000-Word Review, Features, Tools & Engineering Workflow Guide

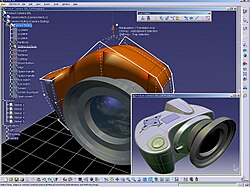

CATIA has been the backbone of advanced 3D engineering, automotive design, aerospace modeling, and product lifecycle management for decades. Developed by Dassault Systèmes, CATIA has always pushed the boundaries of CAD, CAM, and CAE technology. With the release of CATIA V6 R2025, the platform introduces a more powerful, collaborative, cloud-connected, AI-enhanced engineering workflow than ever before. Engineers, designers, manufacturers, and simulation experts now work in a unified 3DEXPERIENCE environment with advanced automation, real-time collaboration, and cutting-edge modeling tools.https://onlinemart.space/

This article provides a complete 2000-word detailed guide covering everything about CATIA V6 R2025—its features, improvements, performance, workflows, industry use-cases, advantages, limitations, and why it matters for next-generation product development.

Introduction to CATIA V6 R2025

CATIA V6 R2025 is the latest major iteration of Dassault Systèmes’ world-class engineering design suite. It continues to build on the 3DEXPERIENCE platform, where designers, engineers, analysts, and manufacturers collaborate through a shared digital environment. The R2025 version integrates deeper AI-assisted modeling, faster geometric kernels, improved parametric control, simulation-driven design, digital manufacturing connectivity, and enterprise-level data management.

As industries transition into smart manufacturing and Industry 4.0, CATIA V6 R2025 provides a seamless environment for end-to-end product development—from concept sketching to solid modeling, surface Class-A design, simulation, manufacturing planning, and lifecycle management.

What’s New in CATIA V6 R2025?

1. AI-Assisted Design Automation

The R2025 version expands AI integration throughout the design workflow. CATIA now predicts user intent, suggests optimized features, automates repetitive modeling steps, and analyzes design defects early. The AI engine helps:

-

Recognize best modeling strategies

-

Recommend constraints and relations

-

Predict optimal surface patch layouts

-

Flag manufacturability issues

-

Auto-complete sketches

This reduces design time by up to 40% in complex assemblies.

2. Enhanced Geometry Kernel

CATIA V6 R2025 uses a refined geometric kernel capable of:

-

Faster Boolean operations

-

More stable surface trimming

-

Improved filleting and variable radius blends

-

Enhanced meshing precision for simulation

Surface designers benefit from smoother curvature continuity (G2/G3) and better transition control.

3. Cloud-Native Collaboration (3DEXPERIENCE Upgrade)

The 3DEXPERIENCE integration in R2025 is deeper and smoother, enabling:

-

Real-time multi-user editing

-

Cloud storage with version control

-

Digital thread connectivity

-

Simultaneous design, simulation, and manufacturing review

-

Secure global collaboration

This eliminates the traditional “file sharing” system and moves to a fully data-driven workflow.

4. Faster Assembly Management

Large assemblies are now handled with:

-

Dynamic Level of Detail (LOD)

-

Multi-core loading

-

Lightweight representation

-

Memory optimization

In aerospace and automotive industries, where assemblies may exceed 10,000+ components, this is a major upgrade.

5. New Surface & Solid Hybrid Modeling Tools

R2025 strengthens hybrid design capabilities:https://onlinemart.space/bitdefender-total-security-2025/

-

Mixed parametric and direct modeling

-

Improved multibody management

-

Class-A surface creation tools

-

Adaptive subdivision modeling

This helps automotive exterior designers, industrial product engineers, and consumer electronics developers achieve higher precision.

6. Simulation-Integrated Design Workflow

CATIA now tightly integrates with SIMULIA, enabling:

-

Real-time structural calculations

-

Fluid dynamics preparation

-

Thermal simulations

-

Kinematic motion studies

-

Generative design optimization

Engineers can validate design decisions instantly without exporting models.

7. Additive Manufacturing Enhancements

For 3D printing workflows, R2025 includes:

-

Improved lattice generation

-

Support structure optimization

-

Build orientation analysis

-

AM-specific topology optimization

This is critical for aerospace and medical device industries.

![]()

Major Features of CATIA V6 R2025

1. Part Design (Parametric 3D Modeling)

CATIA’s Part Design workbench remains one of the strongest in the CAD world. In R2025, it features:

-

Smarter sketch constraints

-

Better geometric relations

-

Robust parametric updates

-

Advanced holes, pockets, pads, and rib creation

-

Multi-body design systems

Users can quickly create mechanical components with high precision.

2. Generative Shape Design (Advanced Surface Modeling)

This is the heart of CATIA for industries requiring Class-A surface quality. R2025 brings:

-

G2/G3 continuity improvements

-

Tangency and curvature comb analysis

-

Sweep enhancement

-

Loft improvements

-

Better surface patch management

Automotive OEMs particularly benefit from these upgrades.

3. Assembly Design

The assembly design workbench enables users to work on massive assemblies with:

-

Constraint solvers

-

Kinematic simulation

-

Clash detection

-

Dynamic motion verification

-

Explosion view tools

With R2025 optimizations, loading and navigation of large models is smoother than previous versions.

4. Drafting & Detailing (2D Drawings)

Manufacturing drawings remain essential. CATIA V6 R2025 includes:

-

Automatic dimensioning

-

GD&T annotation tools

-

Welding symbols

-

Section and detail views

-

Sheet creation automation

Compliance with ANSI, ISO, JIS, and DIN standards is fully supported.

5. 3D Master (Model-Based Definition)

R2025 expands Model-Based Engineering (MBE). Engineers can add:

-

PMI annotations

-

Tolerances

-

GD&T

-

Manufacturing notes

directly inside the 3D model. This reduces the dependency on 2D drawings.https://onlinemart.space/

6. Kinematics & Mechanism Simulation

Motion studies include:

-

Joint creation

-

Gear assemblies

-

Cam systems

-

DOF control

-

Collision simulation

Robotics, automotive, and industrial automation sectors rely heavily on this module.

7. Digital Manufacturing (DELMIA Integration)

When connected with DELMIA through 3DEXPERIENCE, users can:

-

Plan manufacturing sequences

-

Validate robot paths

-

Simulate machining (3-axis & 5-axis)

-

Generate NC toolpaths

-

Analyze material removal

R2025 ensures these workflows run faster and more accurately.

8. Human Design & Ergonomics

For ergonomics engineers, CATIA provides:

-

Virtual manikins

-

Posture analysis

-

Reachability studies

-

Safety compliance analysis

R2025 improves body movement simulation and posture accuracy.

Industries Using CATIA V6 R2025

1. Automotive & Transportation

Used by brands like BMW, Audi, Toyota, and Honda for:

-

Body exterior design

-

Interior styling

-

Engine components

-

Electrical routing

-

Crash simulation preparation

-

Digital manufacturing

Focus on Class-A surfacing makes CATIA the industry leader.

2. Aerospace & Defense

CATIA supports:

-

Composite structure design

-

Aerodynamic surfaces

-

Cabin layouts

-

Simulation model preparation

-

Engine turbine modeling

-

System integration

Airbus was one of the earliest adopters of CATIA because of its capability with huge assemblies.

3. Industrial Equipment

For machinery manufacturers, CATIA helps with:

-

Kinematics

-

Sheet metal

-

Welded assemblies

-

Hydraulic parts

-

Heavy equipment modules

R2025 provides improved thickness and strength analysis.

4. Consumer Electronics

Used for designing:

-

Smartphones

-

Laptops

-

Appliances

-

Wearables

CATIA’s Class-A and hybrid modeling workflow is perfect for modern consumer products.

5. Medical Devices

CATIA helps design:

-

Implants

-

Surgical tools

-

Prosthetics

-

Biomedical equipment

The new topology optimization improves lightweight medical part design.

Performance Improvements in R2025

Faster Load Times

Massive assemblies load up to 30% faster.

Better Multi-Core Utilization

Boolean operations and meshing are now multi-threaded.

More Stable Kernel

Complex surfaces no longer fail during trimming or joining.

Smoother Graphics Pipeline

Real-time shading, reflections, and anti-aliasing have improved.

Advantages of CATIA V6 R2025

-

Extremely powerful for complex engineering

-

Perfect for automotive and aerospace surfacing

-

Advanced collaboration on 3DEXPERIENCE

-

High-quality kinematics and motion simulation

-

Best-in-class Class-A surface tools

-

Supports full digital manufacturing

-

AI-assisted design speeds up workflow

-

Scalable for enterprises

Limitations of CATIA V6 R2025

-

Expensive for individual users

-

Requires strong hardware for large projects

-

Learning curve is steep

-

Heavy dependency on 3DEXPERIENCE connectivity

-

Not ideal for beginners or hobbyists

Who Should Use CATIA V6 R2025?

-

Automotive engineers and exterior designers

-

Aerospace engineers

-

Industry machinery developers

-

Consumer product designers

-

Manufacturing planners

-

CAE engineers

-

Robotics designers

-

Teams working on large assemblies

Is CATIA V6 R2025 Worth It?

Absolutely. CATIA V6 R2025 represents a major leap forward in engineering design technology. The AI improvements, geometry kernel upgrades, and seamless collaboration make it essential for high-level industrial engineering and professional product development.

If your organization values precision engineering, digital twin workflows, or enterprise collaboration, R2025 is a strong investment.

Conclusion

CATIA V6 R2025 is more than just a CAD software upgrade—it is an end-to-end engineering ecosystem built for the future of digital product development. With powerful modeling tools, advanced surface quality, AI-assisted workflows, integrated simulation, and enterprise-level collaboration, it stands as one of the most sophisticated engineering software solutions available today.